Revue de groupe, signature d'un accord de coopération

1. Standards: KFORTS Security Glass Systems—TR Series

|

Burglar Resistance |

Bullet Resistance |

Explosion and Blast Resistance |

|

EN1627 EN1628 EN1629 EN1630 EN356 |

EN1063 EN1522 UL752 |

EN13123-2 EN13124-2 |

2. Burglarproof Glass System: Burglarproof Resistance Performance

| Standards | TR1 | TR2 | TR3 | notes | |

| European Standards |

EN1627 Pedestrian doorsets, windows, curtain walling, grilles and shutters—Burglarproof resistance—Requirements and classification |

RC3 | RC4 |

RC6* |

Note*: KFORTS TR series includes glass door systems, window systems, curtain wall systems, etc. KFORTS can customize your products with one or more resistance performance based on your requirements. |

|

EN1628 Pedestrian doorsets, windows, curtain walling, grilles and shutters—Burglarproof resistance—Test method for the determination of resistance under static loading |

6KN | 10KN | 15KN | ||

|

EN1629 Pedestrian doorsets, windows, curtain walling, grilles and shutters—Burglarproof resistance—Test method for the determination of resistance under dynamic loading |

Resist 50KG pendulum impactor from a height of 750mm. |

No test.** |

No test.** |

||

|

EN1630 Pedestrian doorsets, windows, curtain walling, grilles and shutters—Burglarproof resistance—Test method for the determination of resistance to manual burglary attempts |

Resist tools specified in RC1-RC3 systems, such as 700mm length crowbars and hand drills. |

Resist tools specified in RC1-RC4 systems, such as 0.8KG weight axes and battery drills. |

Resist tools specified in RC1-RC6 systems, such as 1.1KW saber saws and 2.3KW angle grinders. |

Note **: The purpose of EN1629 dynamic impact test is to simulate human attacks without the use of tools, such as shoulder strikes or kicks. When testing RC4-6 systems, the static load shall far exceed the dynamic load, which will not be achieved manually. Therefore, RC4-6 systems do not require dynamic mechanical test. |

|

|

EN356 Glass in building—Security glazing—Testing and classification of resistance against manual attack |

P5A Resist impact 3 times by a ∅ 100mm diameter, 4.11KG weight steel ball from the 9 meters height. |

P6B Resist 30-50 times of the impact by a 2KG axe. |

P8B Resist over 70 times of the impact by a 2KG axe. |

||

3. Bulletproof Glass System: Bullet Resistance Performance

| Standards | TR1 | TR2 | TR3 | notes |

| Corresponding Burglarproof resistance performance | RC3 | RC4 | RC6 |

According to different requirements, clients can customize your TR systems with different bullet resistance performance. |

| European Standards EN1522 Windows, doors, shutters and blinds—Bullet resistance—Requirements and classification |

B1 | B2-4 | B5-7 |

|

American Standard |

Systems |

Rating |

Ammunition |

Grain |

(g) |

Minimum velocity fps (m/s) |

Number of shots |

|

UL752 Standard for safety Bullet-Resisting Equipment |

All TR systems can be customized with bullet resistance performance from one kind of the ratings based on your requirements. |

Level 1 |

9 mm full metal copper jacket with lead core |

124 |

8.0 |

1,175 358 |

3 |

|

Level 2 |

.357 Magnum jacketed lead soft point |

158 |

10.2 |

1,250 381 |

3 |

||

|

Level 3 |

.44 Magnum lead semi-wadcutter gas checked |

240 |

15.6 |

1,350 411 |

3 |

||

|

Level 4 |

.30 caliber rifle lead core soft point |

180 |

11.7 |

2,540 774 |

1 |

||

|

Level 5 |

7.62 mm Rifle lead core full metal copper jacket military ball |

150 |

9.7 |

2,750 838 |

1 |

||

|

Level 6 |

9 mm full metal copper jacket with lead core |

124 |

8.0 |

1,400 427 |

5 |

||

|

Level 7 |

5.56 mm Rifle full metal copper jacket with lead core |

55 |

3.56 |

3,080 939 |

5 |

||

|

Level 8 |

7.62 mm Rifle lead core full metal copper jacket, military ball |

150 |

9.7 |

2,750 838 |

5 |

||

|

Note — Maximum velocity is 110 percent of the minimum velocity.

|

|||||||

4. Blastproof Glass System: Explosion and Blast Resistance Performance

| Standards | TR1 | TR2 | TR3 | notes | |

| European Standards |

EN13123-2 Windows, doors, and shutters —Explosion resistance —Requirements and classification — Part 2: Range test |

EXR1- EXR5* (customized) EXR1=3kg TNT -5-meter explosion EXR2=3kg TNT -3-meter explosion EXR3=12kg TNT - Explosion in 5.5 meters EXR4=12kg TNT - 4-meter explosion EXR5=20kg TNT - Explosion in 5.5 meters |

Note*: EXR is the serial number specified in EN13123-2. You can customize your own products based on local engineering requirements.

|

||

5. Tools and Firearms that TR systems can resist

The resistance performance of TR1 system is equivalent to RC3 resistance level in European standards.

TR1 system can withstand destructive tools and firearms as follows.

| Tool number | Tool specification description |

| A.1 |

Screwdriver; Flat blade, length (365 ± 25) mm, blade width (16 ± 2,2) mm |

| A.2 |

Steel wire; Various diameters up to a maximum diameter of 4 mm, including steel and electrical wire. No restriction on length |

| A.3 |

Locksmiths hammer; head weight (200 ± 20) g, length (300 ± 20) mm |

| A.4 |

Pipe wrench; length (240± 20) mm |

| A.5 |

Set of pin punches; diameters between 3 mm and 10 mm |

| A.6 |

Set of drill-bits; HSS or HS/CO parallel shank twist drills (jobber), Ø 1,0 mm to Ø6,0 mm in steps of 0,5 mm. Only one drill bit of each diameter may be used |

| A.7 |

Universal lock key; including cabinet lock and profile cylinder functions |

| A.8 |

Hand drill; maximum length 355 mm |

| A.9 |

Hacksaw, with two bimetals or HSS blades, blade length (330 ± 30) mm |

| A.10 |

Multiple slip joint gripping pliers; maximum length 260 mm |

| A.11 |

Steel wire; Various diameters up to a maximum diameter of 4 mm, including steel and electrical wire. No restriction on length |

| A.12 |

Pistol; Gun type 54 with 7,62 mm bullets |

The resistance performance of TR2 system is equivalent to RC4 resistance level in European standards.

TR2 system can withstand destructive tools and firearms as follows.

| Tool number | Tool specification description |

| B.1 |

Club hammer; length (300 ± 25) mm, head weight (1,25 ± 0,1) kg |

| B.2 |

Cold chisel; length (250 ± 25) mm, blade width (30 ± 5) mm |

| B.3 |

Wood chisel; length (350 ± 25) mm, blade width (30 ± 5) mm |

| B.4 |

Plate shears; left cutting and right cutting, length (260 ± 25) mm |

| B.5 |

Axe; length (350 + 25) mm, head weight (800 ± 30) g |

| B.6 |

Bolt-cutter; length (460 ± 50) mm |

| B.7 |

Cordless drilling machine; Without percussion action, with two nominal 14,4 V battery packs (up to 3,2 Ah each) |

| B.8 |

Set of drill-bits; HSS or HS/CO parallel shank twist drills (jobber), Ø 1,0 mm to Ø 13,0 mm in steps of 0,5 mm. Only one drill bit of each diameter may be used |

| B.9 |

Submachine gun; Gun Type 79 with 7,62 mm bullets |

The resistance performance of TR3 system is equivalent to RC6 resistance level in European standards.

TR3 system can withstand destructive tools and firearms as follows.

| Tool number | Tool specification description |

| C.1 |

Spalling hammer; length (800 + 50) mm, head weight (3,5 ± 0,25) kg |

| C.2 |

Discs; Ø 230 mm maxi, thickness 3,0 mm (for steel or stone excluding diamond) |

| C.3 |

Saw blades; bimetal |

| C.4 |

Steel wedges; length (200 ± 10) mm, width (80 ± 10) mm, height (40 ± 5) mm |

| C.5 |

Electric jig saw; nominal 650 W± 10 % |

| C.6 |

Angle grinder; Nominal 2 300 W± 10 %, disc diameter max 230 mm |

| C.7 |

Electric drill; Nominal 1 050 W± 10 %, with percussion action |

| C.8 |

Submachine gun; Gun Type 56 with 7,62 mm bullets |

| C.9 |

Sniper rifle; Gun Type 79 with 7,62 mm bullets |

6. More Performances: Building physics

Besides KFORTS high security performance, TR system complies with all requirements in building physics up to highest level. It features a slim frame, a concealed sash design, and a wide visible area.

|

Resistance against wind load |

Water tightness |

Air permeability |

| Technical parameters: ≥ 16kpa/m ³ (1800 * 1500), | Technical parameters: ≥ 700 (PA), | Technical parameters: The unit seam length index value is ≤ 0.5m ³ (m · h),The unit area index value is ≤ 1.4 square meters (m · h),Level: 8 (max). |

|

Air permeability |

Sound Insulation |

| Standard: EN673 | Standard: GB/T 8485-2008, |

|

Technical parameters: 1.87-2.15 W/(㎡· k) Door: 2.158 W/(㎡· k) Window: 1.875 W/(㎡· k) Curtain Wall: 1.873 W/(㎡· k) |

Technical parameters: ≥ 45 (dB (A)), |

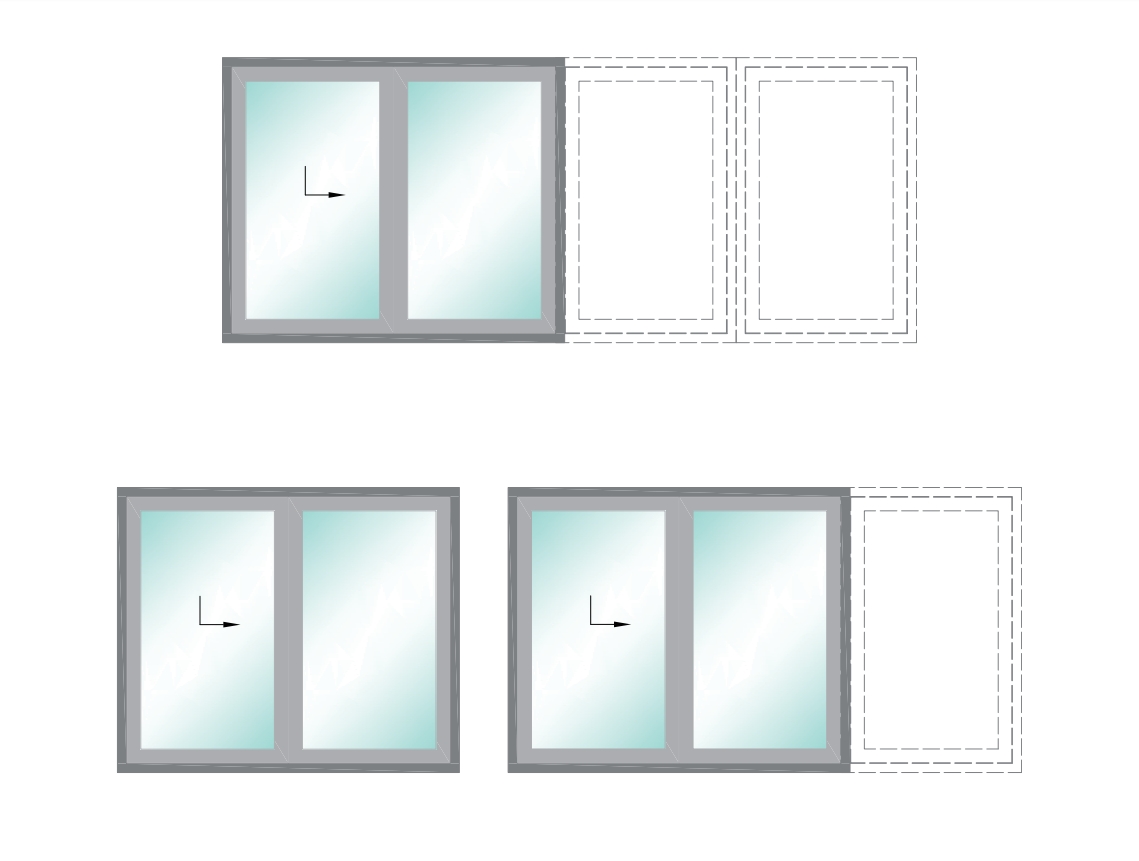

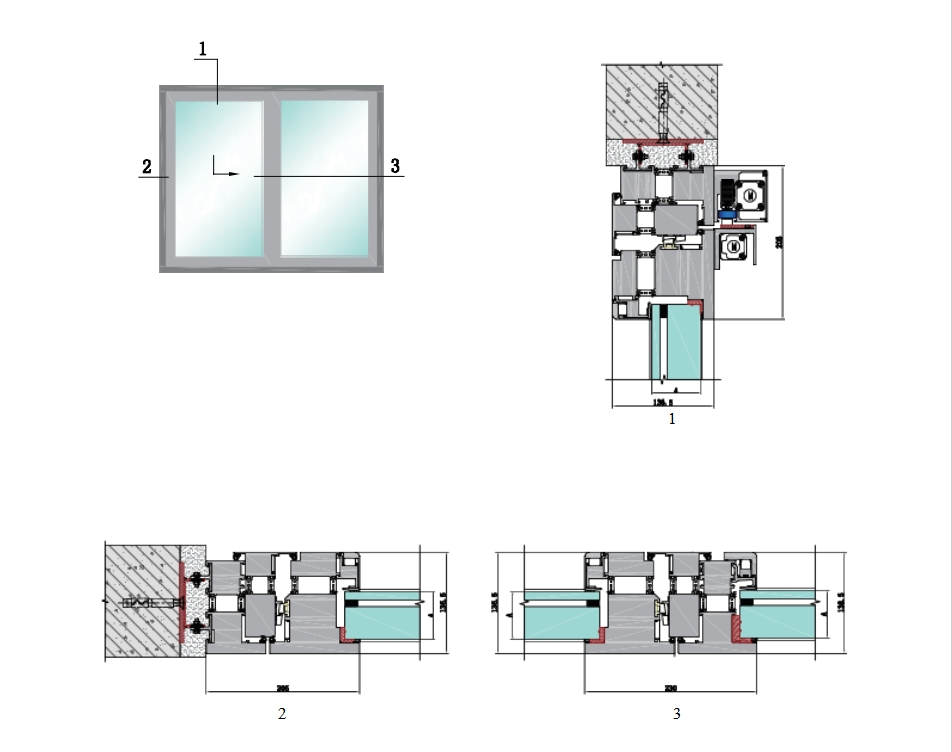

7. Design and Sections

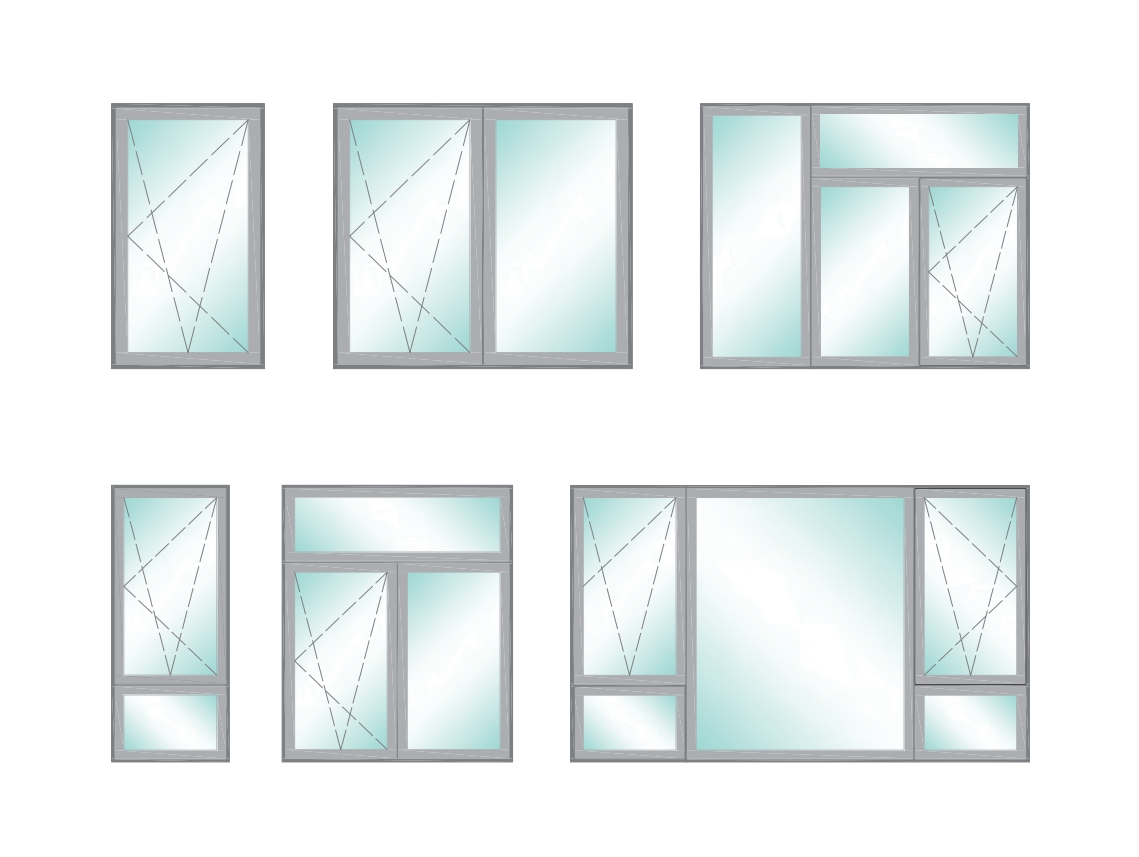

TR Security Glass Window System

Design examples

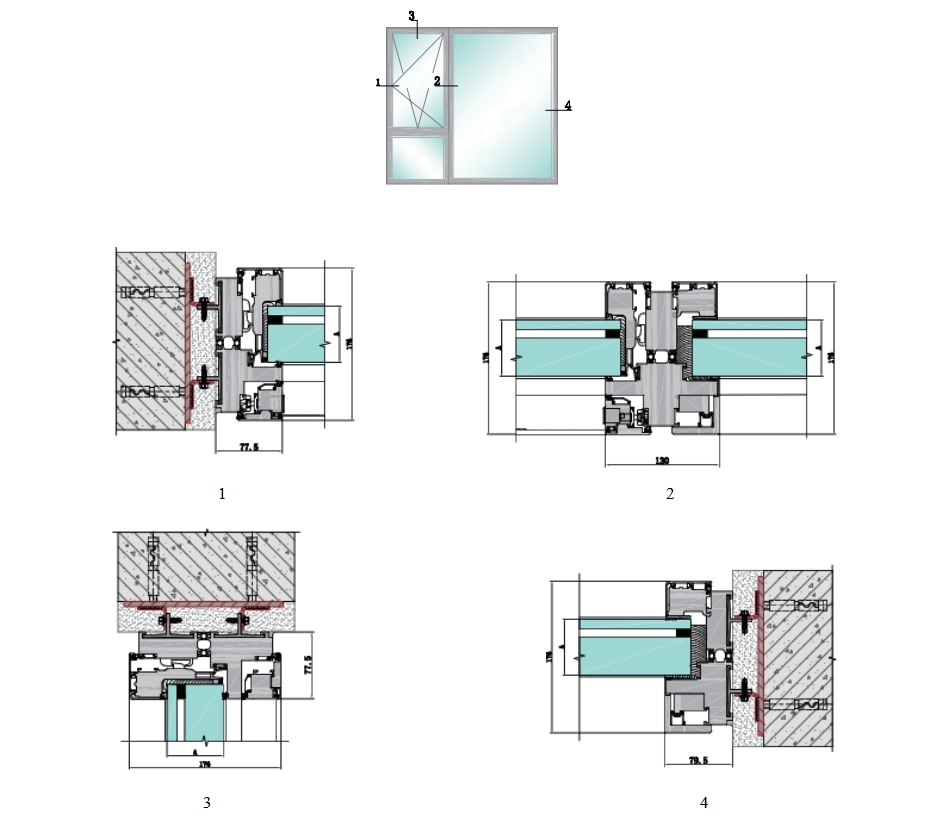

TR Security Glass Window System

Section Examples

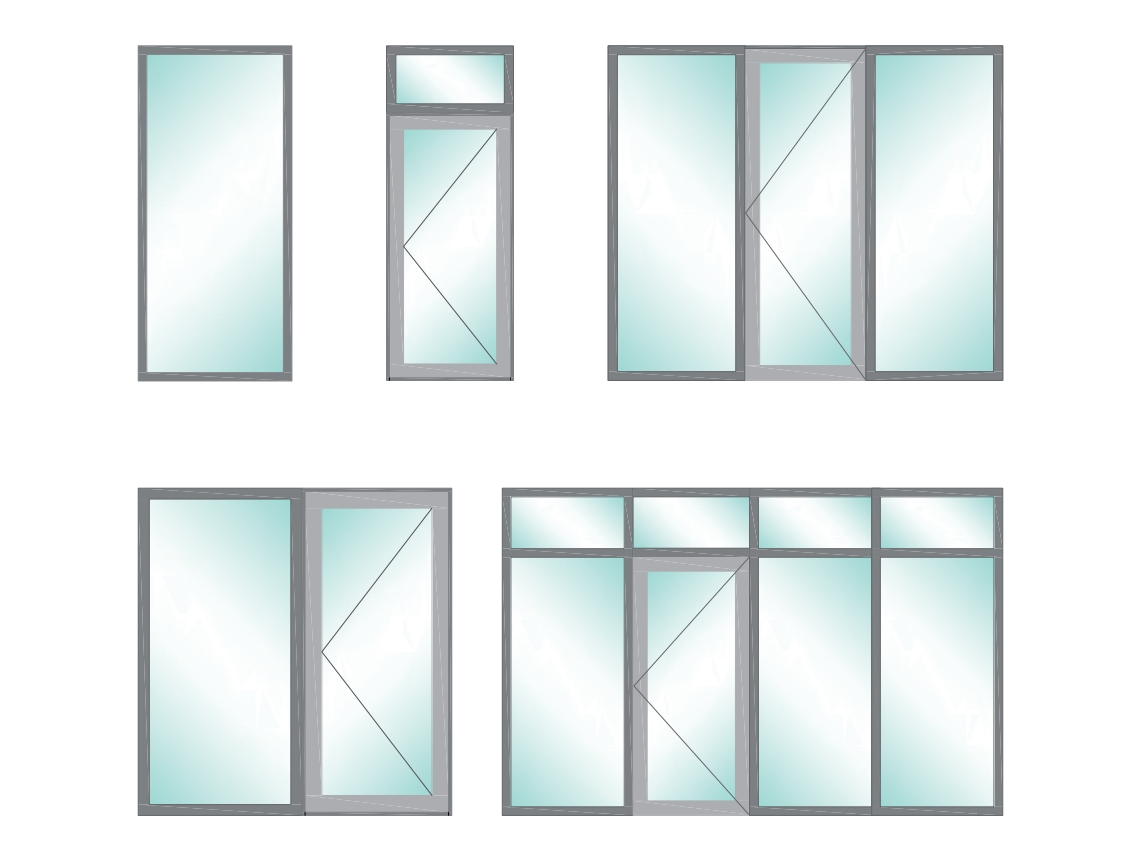

TR Security Glass Swing Door and Curtain Wall System

Design examples

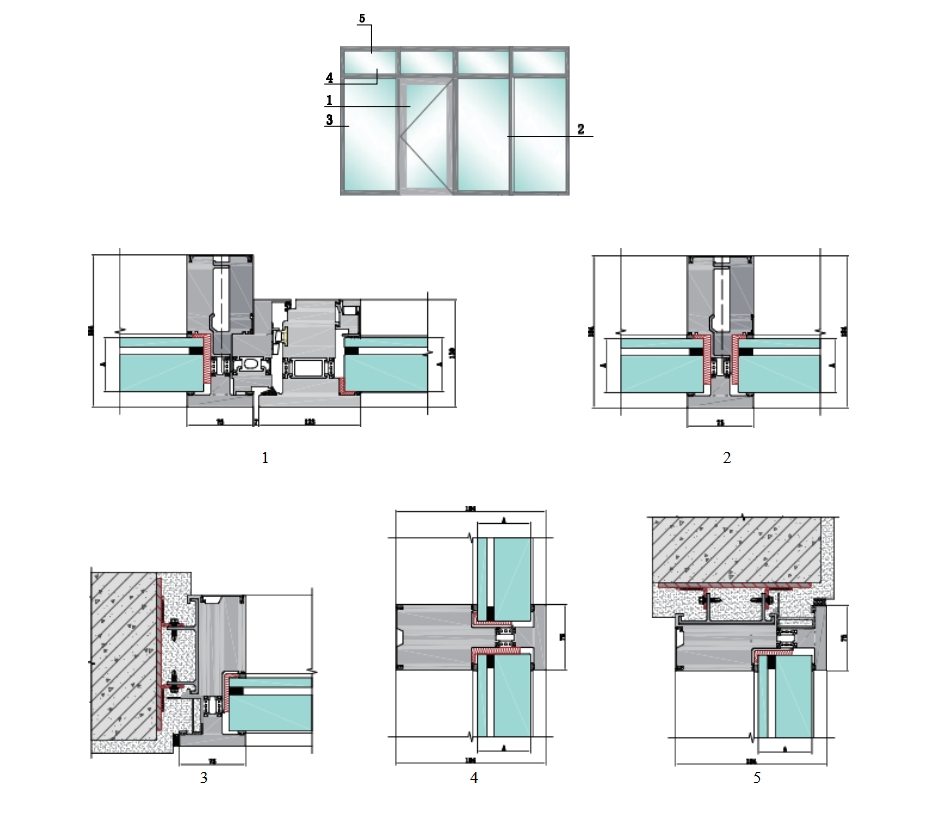

TR Security Glass Swing Door and Curtain Wall System

Section examples

TR Security Glass Sliding Door System

Design examples

TR Security Glass Sliding Door System

Section examples

droits d'auteur

@ 2025 KFORTS Technologie de sécurité Co., Ltd Tous droits réservés.

RÉSEAU PRIS EN CHARGE

RÉSEAU PRIS EN CHARGE